Waste heat from Bell heats Zell school buildings

Until now, around 50,000 liters of heating oil were needed to heat the upper school building in Zell, the double gymnasium and the kindergarten. Now, only waste heat from the nearby Bell Switzerland poultry processing plant ensures that the children and young people have warm classrooms in winter. The innovative heating network has been in operation since the winter of 2022/23. And the project is proving its worth.

Heat from cooling

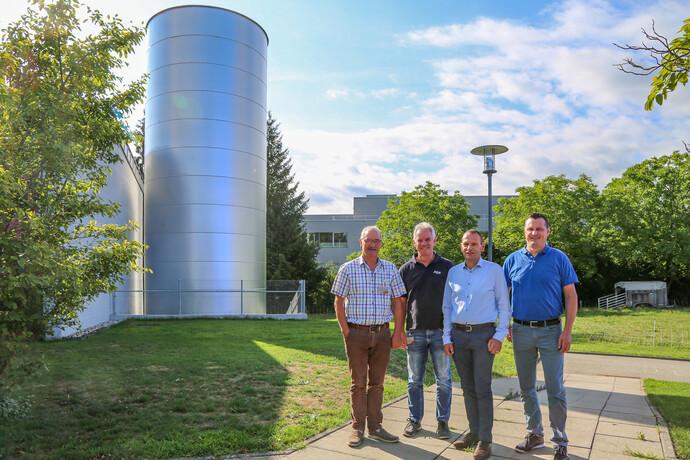

In 2021, Bell put a state-of-the-art high-pressure heat pump with an output of 500 kWh into operation in Zell. This uses the waste heat from the cooling systems and produces water at up to 87 degrees, which is required for the slaughtering process. During the production process, Bell relies on the entire energy production of the plant. However, once the slaughtering process is complete, the plant only needs a fraction of this. Instead of dissipating the surplus heat unused, it now supplies the Zeller Oberstufenzentrum with energy. This flows in the form of hot water from the Bell heating system via a 210-metre long pipeline - which crosses under the Luther stream - to the 120 cubic meter tank next to the multi-purpose school building. This hot water tank is sufficient to supply the two school buildings, the double gymnasium and the kindergarten with enough heat and hot water even on freezing cold days.

Innovative solution

A few years ago, Bell was already planning to replace its existing oil heating system in order to reduce its CO2 emissions. At almost the same time, the municipality of Zell decided to renovate the energy efficiency of the buildings of the upper school center and replace the 40-year-old oil heating system. And the Aargau electricity company AEW Energie AG expressed interest in becoming a contractor for a possible heating network in Zell. Bell, the municipality and the contractor sat down together and developed the solution that has now been implemented, in which there are "no losers, only winners", as Stephan Wolf, Head of Poultry at Bell Switzerland, puts it. "We have a sustainable heating solution, the contractor has a business and the pupils in Zell are pleasantly warm in winter." Municipal councillor Urs Lustenberger is also delighted with the innovative solution: "We successfully mastered the first heating season 2022/23 and saw that the new system works perfectly." Around 15 percent of the energy produced by Bell now goes to the municipality of Zell via the heating network. A smaller proportion also goes to a building cooperative with three apartment buildings, which are also connected to the network.

200,000 liters of heating oil saved

Bell Switzerland invested around 700,000 Swiss francs in the state-of-the-art 500 kWh high-pressure heat pump to replace the existing oil heating system. This project saves Bell around 150,000 liters of heating oil or 400 tons of CO2 per year. The municipality of Zell is saving a further 50,000 liters of heating oil by switching to a sustainable energy supply from waste heat. It invested 175,000 francs in the project, in particular for the distribution and the new hot water system. AEW Energie AG spent around 850,000 francs on the construction of the new heating network in Zell. The costs of heating the upper school center amount to around CHF 50,000 per year.